- Home

- >

- What We Do

- >

- Services

- >

- Busbar Production

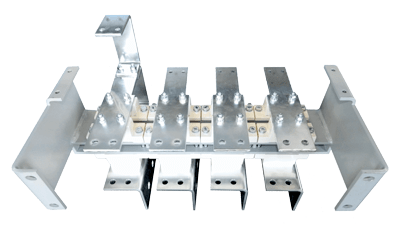

BUSBAR PRODUCTION

LATEST AUTOMATED CNC PUNCHING & BENDING FACILITY FOR COPPER BUSBARS & ALUMINIUM BUSBARS

BUSBAR PRODUCTION

Copper work and busbars for the power & electric industries. Using the very latest fully automated CNC hole cut and forming machines, we can punch and bend to your specification and will manufacture single units to large production runs. In combination with our CNC machine shop, waterjet machining centre or fabrication section, larger or more complex parts can be catered for.

CNC

BUSBAR

PUNCHING

EHRT PROFESSIONAL CNC BUSBAR PUNCHES

High speed, high accuracy 36 Tool CNC busbar punch machine with automatic gantry loading from 50 tonne material storage area. Production schedules loaded direct from ERP with full nesting suite to optimise material and reduce waste.

CNC

BUSBAR

BENDING

EHRT PROFESSIONAL CNC BENDERS

Exceedingly powerful CNC busbar bending machines which achieve an accuracy of +/- 0.2° calculated from the spring back compensation. Complete accuracy and consistency are guaranteed with our busbar assembly.

WE STOCK A COMPREHENSIVE RANGE OF COPPER BAR IN PREFERRED SIZES FOR QUICKER RESPONSE.

LASER

PART MARKING

INTEGRATED AND STAND ALONE LASER MARKING

Integrated laser allows automatic marking of every component, with batch number, part number or logo, thereby improving traceability and adhering to all quality and customer requirements, without additional labour input.

DEBURRING

AND FINISHING

COSTA AUTOMATIC DEBURRING & FINISHING MACHINE

Multi-stage automatic deburring and finishing machine provides a superior finished product with consistent quality.

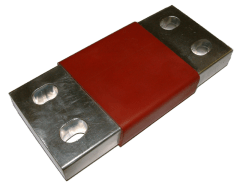

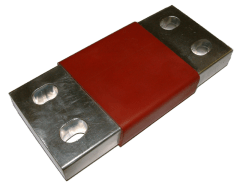

PLATING

PROCESSES

IN-HOUSE TIN PLATING + MANY APPROVED SUBCONTRACT OPTIONS

Our in-house electro tin plating facility allows us to offer both dull and bright tin to specific microns plus we can also supply silver, nickel and zinc plating.

SLEEVING

AND COATING

HEAT SHRINK SLEEVING AND EPOXY COATING

Many options available and stocked… processed using industrial grade ovens and professionally trimmed to customer specification. Epoxy coating also available for more challenging shapes and applications.

Single unit to large production runs.

To schedule, lineside Kanban, Kits, part or fully assembled.

Quality guaranteed

KITTING

AND ASSEMBLY

BESPOKE DELIVERY PACKAGES

Simplified procurement through customised delivery packages including assembled or sub-assembled products, custom packed or kitted up parts to specification. In addition, we can offer deliveries to suit your production schedules.

LASER

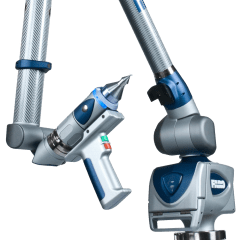

AND FARO INSPECTION

HIGH-TECH LASER & TOUCH BASED INSPECTION

Velden has invested in the very latest inspection equipment to ensure quality standards are maintained and the time required to inspect parts is reduced.