- Home

- >

- What We Do

- >

- Services

- >

- CNC Turning

CNC TURNING

Long time experience and our extensive range of CNC turning facilities enable us to tackle most turning requirements in a rapid cost efficient way with quality guaranteed. Also see our conventional turning facilities.

CNC MILL TURN

MACHINING CENTRES

OKUMA U3000

MULTI-TASKING MACHINING CENTRE

The latest concept multi-tasking mill turn machine with automatic tool changer and 10 inch chuck offers a broad scope of machining functions with power, speed and flexibility to allow components to be machined in one set up.

TWIN SPINDLE TWIN TURRET

MULTI AXIS CNC LATHES

NAKAMURA MULTI-TASKING

TURNING CENTRES

Featuring the latest NT-IPS advanced intelligence control, these automatic machines deliver high quality turned, milled and drilled precision engineered components quicker and at lower cost.

GANTRY LOADED

CNC TURNING CENTRES

TAKISAWA GANTRY

LOADED TURNING CENTRE

Parallel forward facing twin spindle, twin turret 3 axis CNC complete with integrated gantry loading for fast, efficient production of medium sized, lower complexity components.

CNC SLIDING HEAD LATHES

CITIZEN & STAR SLIDING HEAD

CNC LATHES

Our sliding head CNC lathes offer an excellent solution for producing turned milled components and are especially suited to smaller, longer parts. Automated using full size 3m bar feeds, these machines offer continuous, highly accurate, fast production of simple to complex parts, machined complete in a single operation.

ø 42MM

CNC CHUCKING LATHES

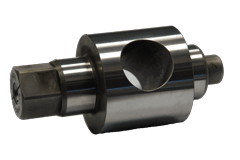

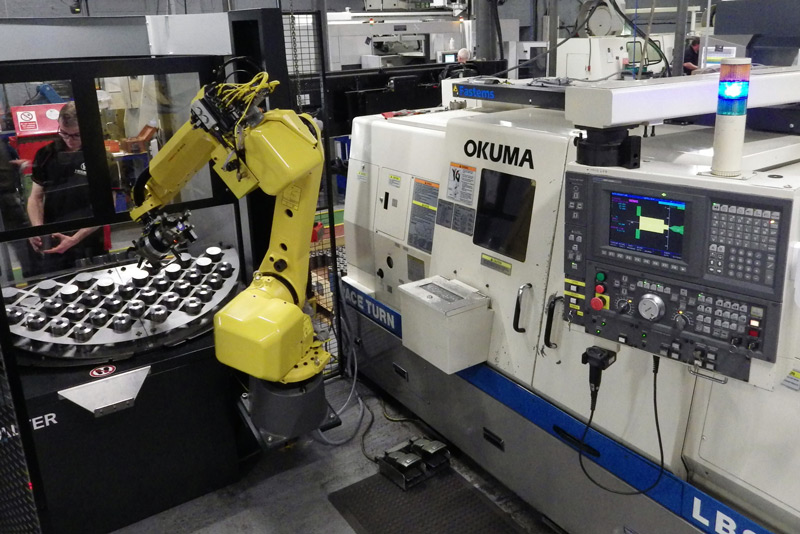

OKUMA CNC LATHES

LOADED BY FANUC ROBOT

Highly versatile machine featuring a programmable C axis plus live tooling. Use of a collet head allows us to machine billets or bars. When loaded with the Fanuc Robot, cost efficiencies are maximised.

KEYENCE VISUAL INSPECTION

KEYENCE

IM6020

“Just place and press” Instant Visual Measurement system which is simpler to operate, saves time, and eliminates variations in measurement interpretation compared to traditional methods. Up to 99 dimensional measurements are taken in a couple of seconds which are conveniently displayed—green (good) or red (bad). The system allows several parts to be measured simultaneously with automatic data recording, built in SPC and reporting system.