- Home

- >

- What We Do

- >

- Services

- >

- Large Parts Machining

LARGE PARTS MACHINING

POWERFUL HEAVY DUTY MACHINERY COMBINED WITH HIGH QUALITY ENGINEERING SKILL FOR CHALLENGING SIZED COMPONENTS

Great experience and skill combined with powerful, heavy duty machinery allows us to machine medium sized billets, castings, forgings and rings from one offs to small production runs.

5-AXIS CNC

BED MILLS

SORALUCE AND KIHEUNG 5-AXIS (3+2) 3M & 6M CNC BED MILLS

Multiple 5-axis CNC bed milling machines with automatic universal heads, Renishaw probes and indexing table – perfect for larger jobs up to 6m in length.

VERTICAL

BORING

48″ & 36″ WEBSTER BENNETT

VERTICAL BORERS WITH ELEVATING RAIL & DRO’S

Manual machining allowing flexibility for those one off and small batch requirements.

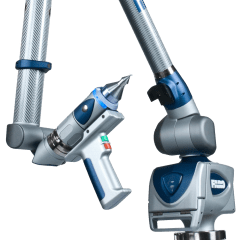

FARO INSPECTION

TOUCH BASED INSPECTION

Velden has invested in the very latest inspection equipment to ensure quality standards are maintained and time required to inspect parts is reduced.